AN ISO 9001 : 2008 CERTIFIED CO

AN ISO 9001 : 2008 CERTIFIED CO

There are numerousfactors affecting accuracy and precision of 3D printer and it varies accordingly to printer type. In FDM printer accuracy depends mostly on extrude size and accuracy of motor while accuracy of DLP printer depends on X/Y resolution, accuracy of motor and many other factors.In this blog we will explore parameters of additive manufacturing machines that affect accuracy of part.

Resolution

One thing is same in all additive manufacturing technique (AM), part is produced layer by layer and each layer has some levels of details which is known as resolution. FDM printer has extruder head to move in X axis and Y axis and both movements are controlled by separate motor. So, resolution of FDM printer are controlled by individually motors. In case of DLP printer, resolution of layers is depends on pixel density of projector. High density of pixels will deliver accurate part. In DLP printer it called X/Y resolution and its unit is microns. It suggests size of one pixel. In SLA printer resolution of layers depends on the size of laser beam. Generally, size of laser beam is 100um to 300um.So check the X/Y resolution of any 3D printer ordering.

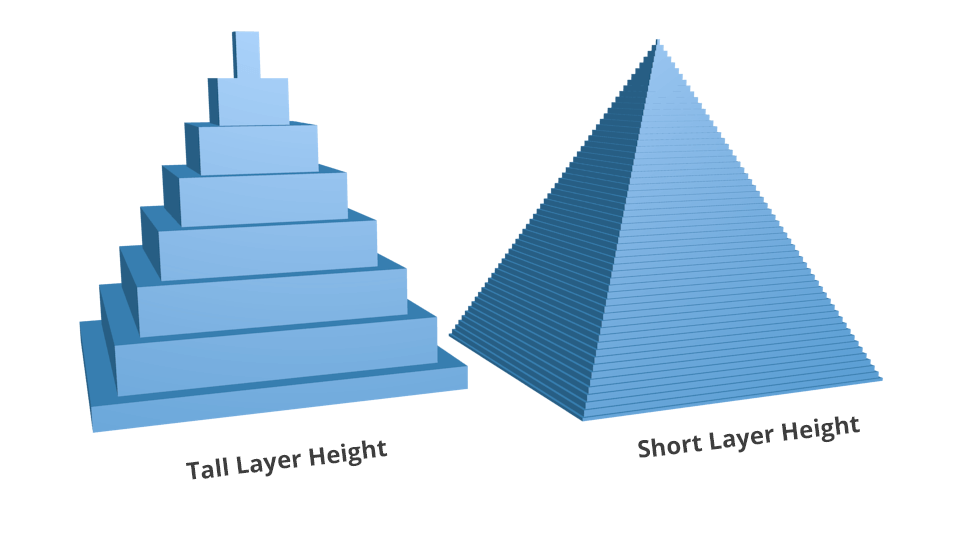

Layer Thickness

Additive Manufacturing Technique produce 3D part by adding layers so thickness of all layers affects the quality of print. FDM printer moves head or bed in Z axis to support the layers. Extruder head lay the layers of specific thickness in bed. Quality of print in FDM depends on layer thickness and motors of X & Y axis. DLP printers are more accurate than FDM printers in terms of layer size and resolution. Advanced DLP printer can print up to 10um thickness while FDM printers are still controlled to 100um.

Materials

Accuracy of printed part depend on material. There are many materials available for FDM and DLP printer and still being developed by companies to increase the application of 3D printer. Mostly FDM printer are used for industrial and automotive part or prototype where strength is more needed rather than quality while DLP printer are used in medical, jewelry casting and other part printing where quality and strength both are needed. In DLP printer different resins are available for various application and properties of all resin are different from one another. Some resin can print layers up to 10µm thickness while some resin can print layers of only 100µm therefore accuracy of your printed part depends on material.

Post Processing

Post processing is essential to achieve desired look and feel. Generally, FDM printer have rough finish, which is visible to eye but they can be easily post - processed to achieve the desired properties using acetone. DLP printer have smooth finish but strength of printed part can achieve by curing the model in UV light and same for the SLA printer.During post processing shrinkage is occurred in resin part due to over curing while FDM parts also lost its dimension after post processing so user need to compensate the dimensional error of post processing part during printing.

Achieving accurate 3D parts requires attention to software, post processing and other tools. Integrate set up of complete system produce more accurate parts.There are lots of other characteristics to study when estimating 3D printer’s capability. What mechanical properties do your partrequire? One of the best ways to get started is to see real printed parts. Choose a free sample from Shapet in a variety of materials to see quality of printed parts.