|

|

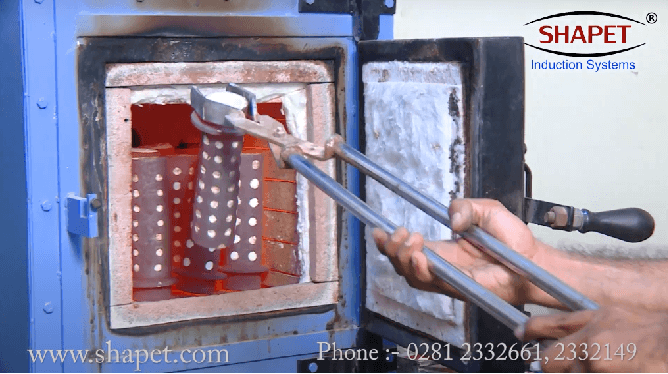

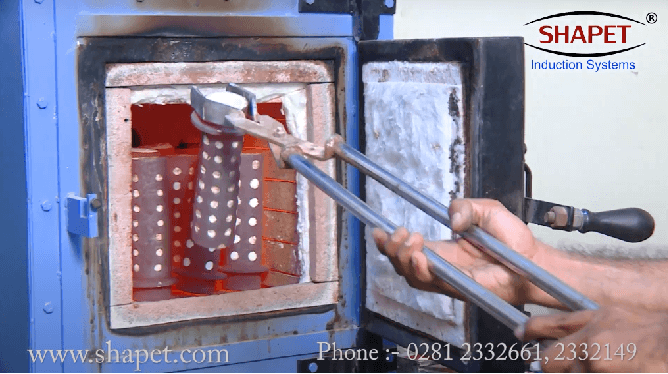

The burnout furnace is a crucial tool used in the process of jewellery casting. It is specifically designed to eliminate the wax from the mould before the molten metal is poured in. This furnace operates at high temperatures, typically ranging from 700 to 900 degrees Celsius, ensuring the complete removal of the wax without causing any damage to the mould. The furnace is equipped with a programmable controller that allows for precise temperature control and timing, ensuring consistent and reliable results. The interior of the furnace is lined with a refractory material that can withstand the extreme temperatures and protect the surrounding environment. Additionally, the furnace is equipped with safety features such as an automatic shut-off system and temperature sensors to prevent overheating and potential accidents. Overall, the burnout furnace is an essential tool for jewellery casting, providing a reliable and efficient method for removing wax and preparing the mould for the casting process.

| Specifications |

| Power Supplier |

Single Phase And Three Phase |

| Voltage |

230 Volt AC |

| Maximum Temperature |

0Ëš - 850Ëš C |

| Temperature Measurement |

Digital (K-Type) |

| Programmable Timer |

Maximum 9 Steps |

| † Brimful Capacity †† Under Standard Condition |

| Benefits |

| The rotary burnout oven features a robust construction with high-quality materials to withstand high temperatures and heavy-duty usage. |

| Equipped with powerful heating elements strategically positioned around the chamber to provide even heat distribution. |

| Offers a wide temperature range suitable for various materials and applications, typically ranging from ambient to over 1000 degrees Celsius. |

| Incorporates safety features such as thermal insulation, overheat protection, and emergency shut-off mechanisms to prevent accidents and ensure operator safety. |

| Designed with a user-friendly interface for easy operation and monitoring of the burnout process. |

| Designed for ease of maintenance, with accessible components and minimal downtime for routine servicing. |

| Highlights |

| Surround heating coil to ensure uniform heating of all flasks. |

| Use PID Temperature Control for Accurate Temperature Measurement |